Custom Molding and Prototyping

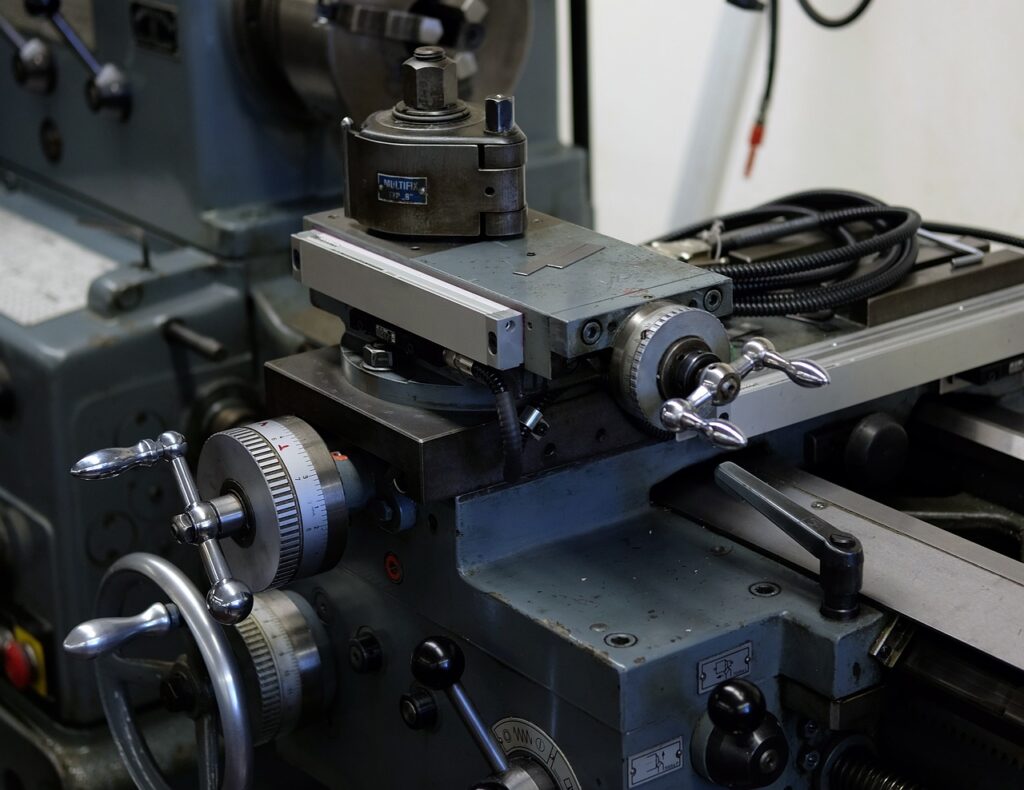

- Product Design and Prototyping: SRS ENT provides assistance in designing and prototyping plastic components. They use specialized software and expertise to turn clients’ ideas into 3D models and physical prototypes for testing and validation.

- Custom Molding: SRS ENT produces custom plastic parts in large quantities. They work with clients to understand their specific requirements and create molds tailored to the desired product specifications.

Mass Production of Plastic Components

High-Volume Production: One of the primary services offered by SRS ENT is mass production of plastic parts using injection molding. Once the mold is created, it allows for efficient and cost-effective production of large quantities of identical plastic components. This is particularly valuable for industries such as automotive, electronics, and consumer goods

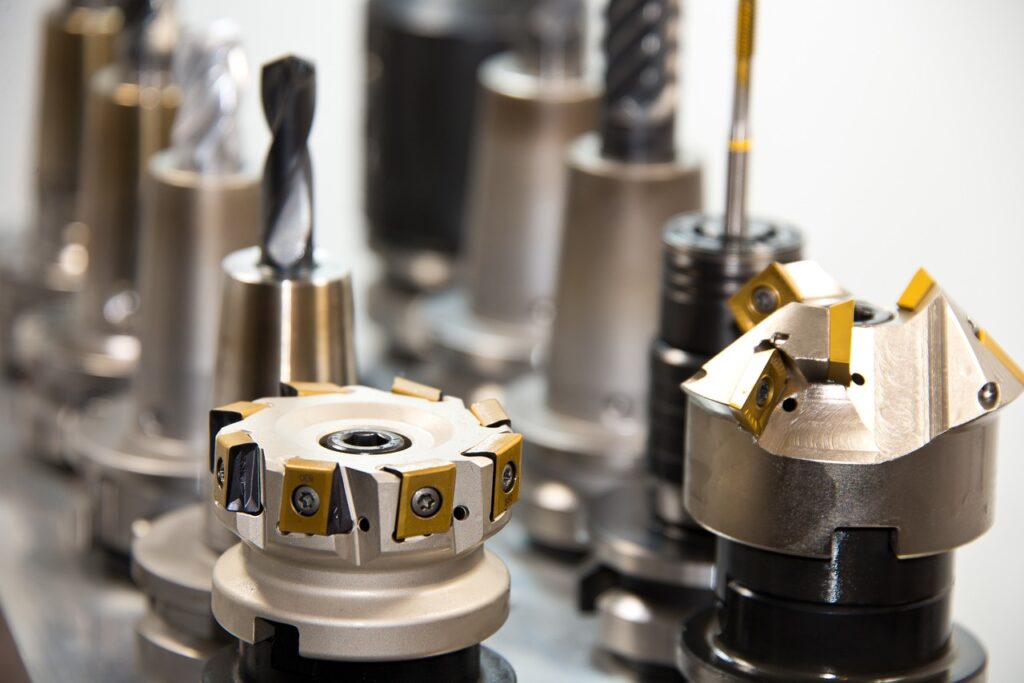

Material Selection and Expertise

- Material Consultation: Injection molding SRS ENT often assists clients in selecting the most suitable plastic materials for their applications. They consider factors such as strength, durability, flexibility, and cost to ensure that the chosen material meets the specific needs of the project.

- Quality Control: SRS ENT has quality control measures in place to ensure that the produced plastic parts meet industry standards and client specifications. This includes monitoring the injection molding process, inspecting finished products, and conducting tests to verify material properties

Talk to us

Have any questions? We are always open to talk about your business, new projects, creative opportunities and how we can help you.